Magnesium Oxide MgO insulating properties applied to cable fillers

Release Time:

2022-04-02

Activated Magnesium Oxide MgO has the remarkable characteristics of good insulation performance.

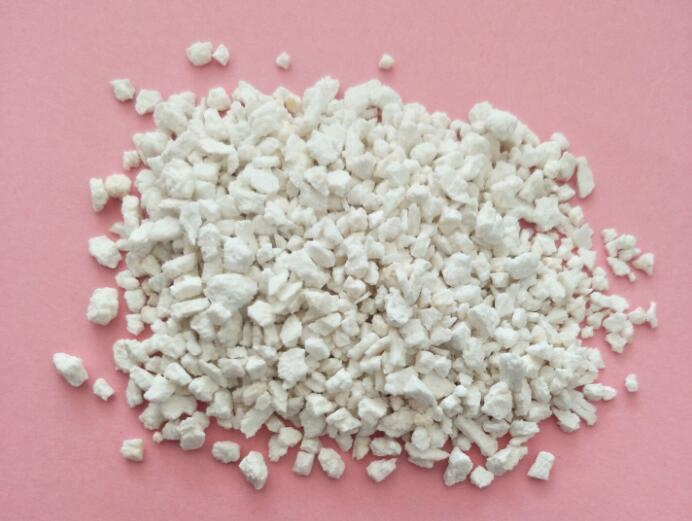

Activated Magnesium Oxide MgO has the remarkable characteristics of good insulation performance. The physical properties of activated magnesium oxide have a certain influence on the insulation performance of magnesium oxide. The raw material technology used for magnesium oxide powder with excellent insulation performance comes from salt lake brine, mining cables in the market, etc. For products with special requirements for insulation, the demand for Magnesium Oxide MgO materials with high insulation is increasing.

Magnesium Oxide MgO affects its insulating performance by controlling the particle size of magnesium oxide powder by controlling the calcination temperature and calcination time. Through research, it is found that the degree and level of internal defects of magnesium oxide have little relationship with the insulating performance of magnesium oxide. The method is to modify the magnesium oxide to increase the temperature, time and usage rate of the modifier for the modification of the magnesium oxide, and the insulating properties of the magnesium oxide will be further improved.

When producing CPE cables, white power cords, mining cables, and fireproof cables that require appearance and insulation, the effect of adding light magnesium oxide to the filler is better than that of heavy magnesium oxide and magnesium hydroxide. High, low impurity content, good stability, good dispersibility, fine particle size, flame retardant and other remarkable product characteristics, can quickly absorb and absorb hydrogen chloride, absorb and absorb acid gas during rubber mixing.

The use of high-end lightweight Magnesium Oxide MgO in the cable industry is the development trend of the cable industry, and it is a reaction brought about by industrial upgrading.