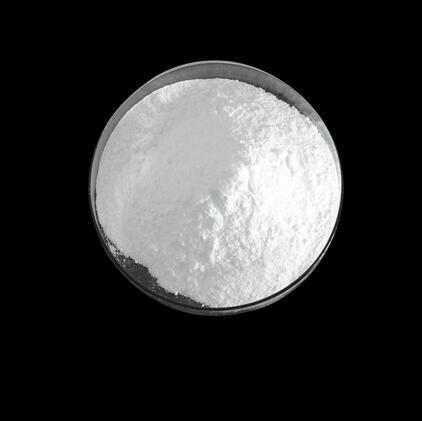

Dry preparation of Barium Fluoride BaF2

Release Time:

2022-08-11

Dry method, also known as solid-phase synthesis method, uses barium fluorosilicate to decompose into products Barium Fluoride BaF2 and silicon tetrafluoride gas at high temperature. , and then react with barium hydroxide or barium carbonate to obtain silicon tetrafluoride gas and reuse it after absorption. The reaction equation involved:

Dry method, also known as solid-phase synthesis method, uses barium fluorosilicate to decompose into products Barium Fluoride BaF2 and silicon tetrafluoride gas at high temperature. , and then react with barium hydroxide or barium carbonate to obtain silicon tetrafluoride gas and reuse it after absorption. The reaction equation involved:

Advantages and disadvantages: the raw materials used are easy to obtain, the price is low, the preparation process is simple, the equipment required is less, the by-products of the reaction are easy to handle, the production process has no waste water, waste liquid discharge, no secondary pollution, and has good economic benefits and environment. benefit. However, the temperature required for thermal decomposition is high, the energy consumption is large, and the requirements for production equipment are high. When the barium fluorosilicate is pyrolyzed at high temperature, the heat transfer is not uniform, which is easy to cause the phenomenon of wall formation, which increases the energy consumption, and also affects the purity of the final solid product. The use of fluidized bed for thermal decomposition can solve this problem.

The above is the relevant explanation about the dry preparation of Barium Fluoride BaF2, I hope it can help you.