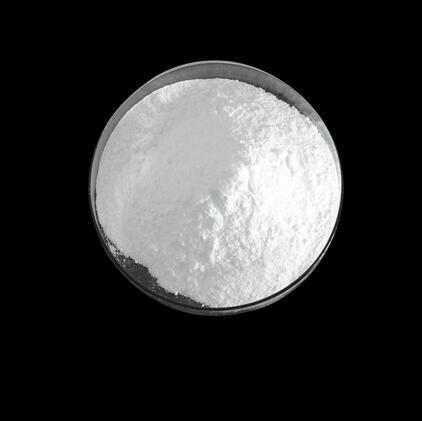

Manufacturing process of Aluminum Fluoride AlF3

Release Time:

2023-02-23

After crystallization, filtration, high-temperature calcination and dehydration, the Aluminum Fluoride AlF3 product is finally obtained.

(1) Wet method, using acid-grade fluorite powder, concentrated sulfuric acid and aluminum hydroxide as raw materials, first absorbing the hydrogen fluoride gas generated by the reaction of acid-grade fluorite powder and concentrated sulfuric acid with water to obtain aqueous hydrofluoric acid with a content of 30%, Make it react with aluminum hydroxide in a liquid-solid mixed phase to obtain a supersaturated Aluminum Fluoride AlF3 solution. After crystallization, filtration, high-temperature calcination and dehydration, the Aluminum Fluoride AlF3 product is finally obtained.

(2) The dry method is the same as the wet method. It also uses acid-grade fluorite powder, concentrated sulfuric acid and aluminum hydroxide as raw materials. The contained dust and sulfuric acid are then mixed with dry aluminum hydroxide (water content 12%) and sent into a double-layer fluidized bed to complete the two-step reaction of roasting, dehydration and fluorination, and finally produce Aluminum Fluoride AlF3 products.