Effect of Magnesium Oxide MgO Dispersibility

Release Time:

2022-05-30

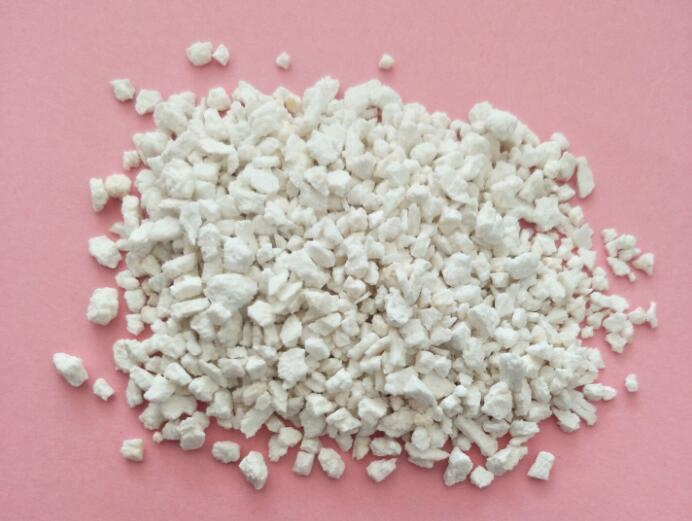

Magnesium Oxide MgO is an emerging additive, especially the lightweight Magnesium Oxide MgO is the leader among Magnesium Oxide MgO. Lightweight Magnesium Oxide MgO is different from ordinary Magnesium Oxide MgO, and has certain unique markets and application scenarios.

Magnesium Oxide MgO is an emerging additive, especially the lightweight Magnesium Oxide MgO is the leader among Magnesium Oxide MgO. Lightweight Magnesium Oxide MgO is different from ordinary Magnesium Oxide MgO, and has certain unique markets and application scenarios.

Magnesium Oxide MgO plays a role in promoting vulcanization and preventing scorch in the rubber compound. To give full play to this characteristic, it is necessary to pay attention to the dispersibility of Magnesium Oxide MgO. Products with poor dispersibility will lead to the occurrence of raw materials in the rubber compound, and the final There are many white spots on the product compound, and even the consequence of the compound being scrapped. The good dispersion of Magnesium Oxide MgO can well promote the vulcanization and scorch prevention of the compounded rubber, especially in the rubber mixing process, to prevent the occurrence of Gelatinization and scorch phenomenon, the viscosity of Magnesium Oxide MgO is the direct reason that affects its dispersibility, Magnesium Oxide MgO is sticky and has poor dispersibility;

The viscosity of Magnesium Oxide MgO is directly related to the physical indicators of Magnesium Oxide MgO, such as the particle size and mesh number of Magnesium Oxide MgO, and it is also related to the raw material industry of Magnesium Oxide MgO. The products of brine method have higher viscosity than ore method.